15

2024

-

03

Troubleshooting of Rock Drill Truck Inoperative after Power Replacement

After working for more than 6 months, a Boomer282 full hydraulic rock drilling rig suddenly appeared the following failure phenomena: when 380V power is used as the power source, its work is completely normal, but when the charger is used for charging, its indicator light shows that the battery is not charged properly; When the diesel engine is used as the power source, the hydraulic system of the trolley cannot work.

A Boomer282 type full hydraulic rock drilling jumbo suddenly appeared the following failure phenomenon after working for more than 6 months: when 380VWhen the power is used as the power source, its work is completely normal, but when the charger is used for charging, its indicator light shows that the battery is not charged normally; when the diesel engine is used as the power source, the hydraulic system of the trolley cannot work.

A Boomer282 type full hydraulic rock drilling jumbo suddenly appeared the following failure phenomenon after working for more than 6 months: when 380VWhen the power is used as the power source, its work is completely normal, but when the charger is used for charging, its indicator light shows that the battery is not charged normally; when the diesel engine is used as the power source, the hydraulic system of the trolley cannot work.

By the fault phenomenon, the fault may be in the hydraulic system or circuit part.

1.Fault Analysis of Hydraulic System

When the diesel engine is used as the power, the hydraulic system of the trolley cannot work, which may be caused:

(1) The working pressure of the hydraulic system is adjusted too low, or the spring force of the pressure regulating valve is insufficient or broken.

(2) The oil leakage of the oil pipe is serious, causing the system pressure to be too low.

(3) The hydraulic cylinder seal is damaged, causing internal leakage of the hydraulic cylinder.

(4) operating valve due to serious wear and tear, leakage.

(5) The gear or end cover of the hydraulic pump is severely worn, causing internal leakage of the hydraulic pump and making the system pressure not meet the requirements.

For the first possible cause (1), the car has adjusted the pressure to normal at the beginning of work, and has been working normally for more than 6 months. The sudden phenomenon of low pressure cannot be the cause of pressure adjustment or the lack of spring elasticity of the pressure regulating valve. It may be caused by the spring fracture of the pressure regulating valve.

For possible cause (2), check that there is no oil leakage from the oil pipe.

For the possible reasons (3) and (4), since there are two power systems of the trolley, the other parts of the hydraulic system (including the hydraulic cylinder and the control reversing valve) are shared except that the two wave pressure pumps driven by the electric motor or the diesel engine respectively supply the pressure oil. The hydraulic system of the vehicle diesel engine cannot work, but it works normally when the motor is used, which indicates that the hydraulic cylinder of the trolley has no internal leakage and the steering valve does not leak.

For the possible reason (5), because there are two power sources of the trolley, when the diesel engine drives the hydraulic pump, it cannot work normally, and the electric motor drives the hydraulic pump to work normally, indicating that the fault is most likely to be driven by the diesel engine. On the hydraulic pump.

2.Fault analysis of circuit part

The cause of abnormal battery charging lies in the circuit part of the trolley, which may be caused by short circuit or open circuit of the charging circuit, or may be caused by fuse burning, circuit disconnection or circuit grounding.

3.Troubleshooting of hydraulic system

First of all, the pressure regulating valve of the trolley was disassembled and inspected, and it was found that the spring of the pressure regulating valve was intact, which proved that the cause of the failure was not here.

Secondly, the oil pressure gauge is used to detect the output pressure of the hydraulic pump driven by the diesel engine, and the pressure is normal; at the same time, the pump is disassembled, and the gear gap and end face gap are measured. The result is too large but within the allowable range; the end cover is carried out Grinding to make the gap meet the standard, and the machine is tested after installation, but the fault has not been eliminated. It can be seen that the fault is not on the hydraulic pump.

4.Circuit System Troubleshooting

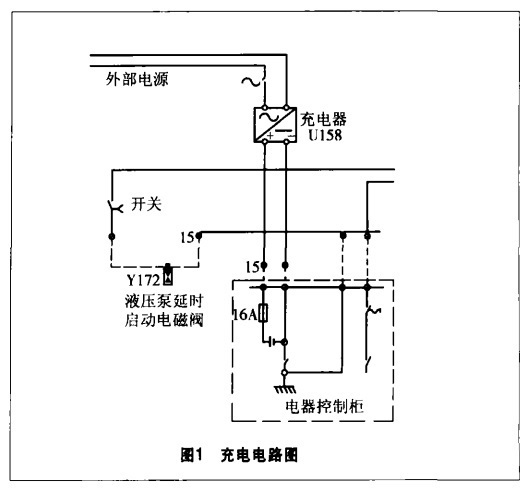

The trolley is electro-hydraulic control, and the phenomenon of abnormal battery charging is analyzed as follows according to Figure 1. U158 is a charger, which charges the battery after 380V power is reduced; Y172 is a hydraulic pump delay start control solenoid valve, and the charging circuit of the battery or battery is used as the power source. The battery charge indication is not normal, most likely due to the 16A fuse blown in the figure.

The fuse was disassembled and inspected, and it was found that it had been blown. After replacing the fuse, the machine was retested and the fault was eliminated.

Why does a small fault in the circuit system cause the hydraulic system to not work properly?

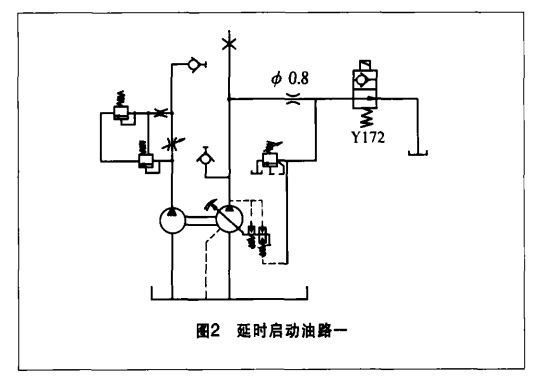

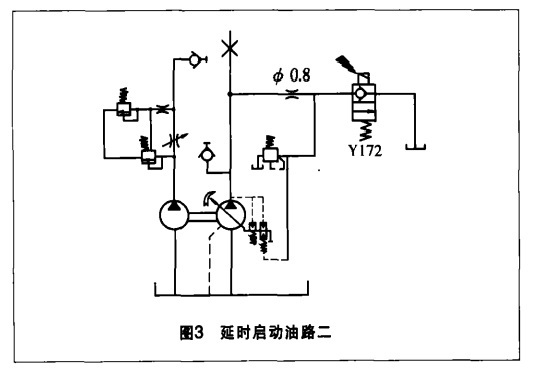

The reason is: in order to facilitate the start, the hydraulic system of the trolley adopts a delayed no-load start system, and its main control element is the Y172 valve in Figure 1. The valve is a delay solenoid valve, power 3s after the spool will automatically reverse, change the flow of hydraulic oil and maintain the state, until the power after the spool in the spring automatically returned to the initial state. Its function in the trolley hydraulic system is:

(1) As shown in Figure 2, when the system starts to start, the Y172 valve is in the position shown in the figure. At this time, the oil pumped by the hydraulic pump passes through the throttle valve (φ0.8mm) hole and Y172 under the action of the resistance of the hydraulic system. The solenoid valve flows directly back to the oil tank, and the system has no load, so that the motor or diesel engine can be easily started.

(2) As shown in Figure 3, when the motor or diesel engine is started, under the delay action of the Y172 valve, after 3s, the spool of the Y172 valve starts to move to the position shown in the figure, and the unloading oil circuit of the hydraulic system is closed and transferred to Normal working state. After the pressure oil pumped by the variable pump flows through the throttle valve (φ0.8mm) hole, part of it is used to adjust the pressure and flow of the variable pump output pressure oil to adapt to changes in external load during work. It can be seen that whether the Y172 valve is energized will directly affect the normal operation of the hydraulic system. The two nodes marked 15 in fig. 1 are the same nodes. if the diesel engine is used as the power, the Y172 valve uses the battery as the power supply. however, when the fuse 16A is burned out, the battery will not be able to supply power to the Y172 valve and the Y172 valve will not work. as a result, the hydraulic system will always be in an unloading state. therefore, the hydraulic system will not work when the diesel engine is used as the power.

From the above troubleshooting process, the technology is developing, and the maintenance concept should also be changed. If you want to do a better job of maintenance, you should open your mind and recognize that the failure of the hydraulic part may be in the circuit part and the circuit part. The fault may also be in the hydraulic part.

RELATED INFORMATION