link:LHS Rock Tools

All Rights Reserved by LHS Rock Tools. 辽ICP17002219号 Website:www.300.cn jinzhou.300.cn

News

Great antiquity and profession

How to fix the cemented carbide on the bodies of button bits

How to fix the cemented carbide on the bodies of button bits

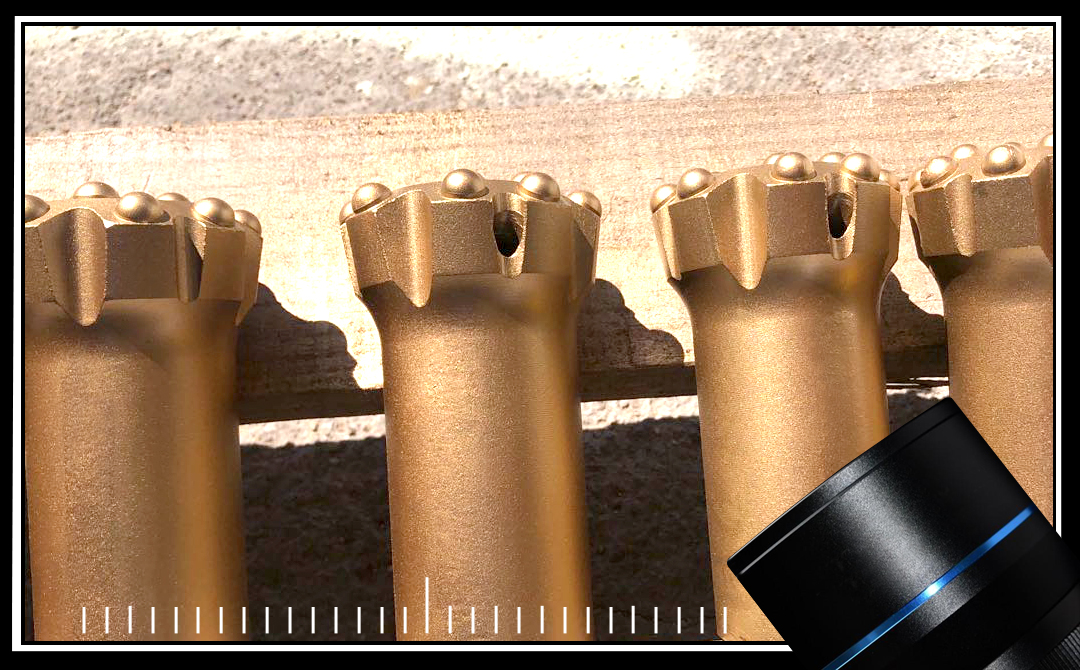

The fixing method refers to how to fix the cemented carbide on the bodies of button bits. At present, there are three methods of welding, cold pressing and hot inserting in Chinese drilling tool industry.

1)The welding process, as the oldest one, is relatively simple. According to the sizes of button holes and buttons, which are determined by welding gap, carbide buttons are welded by copper or silver into button holes arranged on the bodies based on the structure. The requirements for hole accuracy and button sizes are not high. The welding process has disadvantages of difficult operation, easy welding scars left to affect the appearance, high welding vacancy, low welding strength, and short service life of drill bits. The welding process is mostly used for manufacturing tapered button bits with small diameters, and has been gradually eliminated.

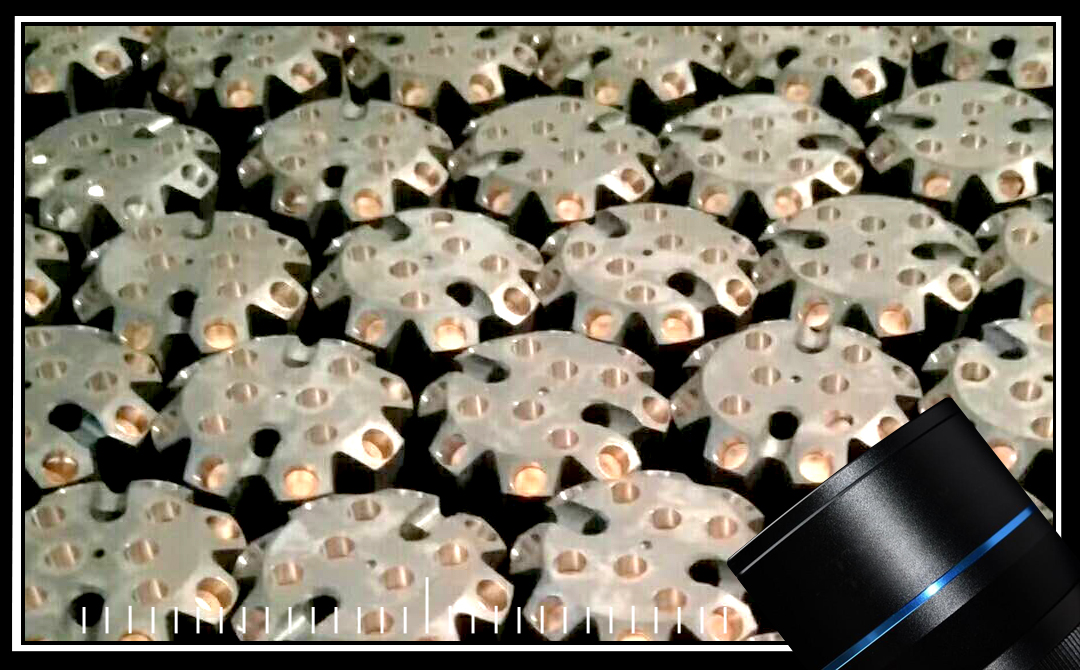

2) The cold fixing process (cold pressing process) is currently used by most factories. The key point of the process is to calculate the fit clearance between button holes and carbide buttons according to the yield limit of body steels, and press buttons into holes by external force according to the interference fit method. The cold pressing process has the characteristics of easiness, high efficiency and low stability. When buttons are pressed into button holes, bodies and buttons may be easily flawed under the action of external force. Therefore, the overall service life is limited. Especially at the late period of service life, it is easy to lose buttons, break buttons, etc. Now the cold pressing process is mainly used for threaded button bits which are relatively low in requirements or not used for repeated grinding.

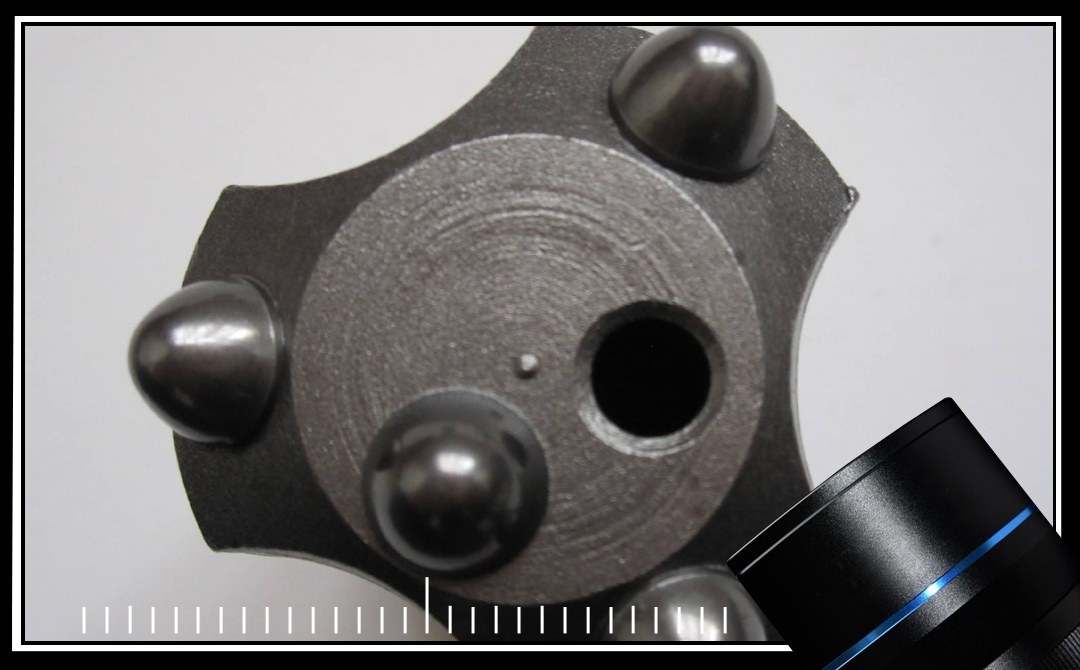

3)For threaded button bits with high requirements, the hot inserting process is recommended. Buttons should be inserted into bodies with good thermal expansion and toughness by appropriate interference according to differences in thermal expansion when bodies and buttons are under the same heating condition. Compared with button bits of the cold pressing process, button bits of the hot inserting process are suitable for repeated grinding and have the advantages of better body materials, higher strength, higher hardness, stronger adaptability and better stability.